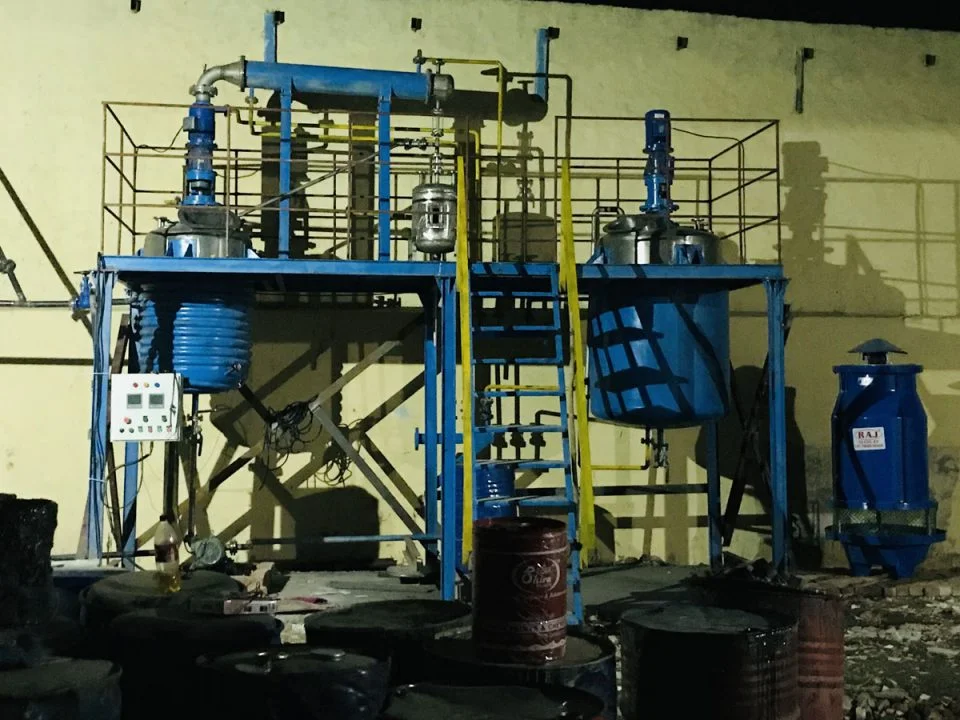

Alkyd Resin Plant

Alkyd Resin Plant

Manufacturing Excellence with Charmi Engineering

At Charmi Engineering, we specialize in designing and manufacturing advanced Alkyd Resin Plants that cater to the needs of modern industries. Alkyd resins are one of the most versatile synthetic resins, widely used in the production of paints, coatings, varnishes, and adhesives. Our state-of-the-art plants are designed to provide high efficiency, superior quality, and sustainability, enabling our clients to deliver top-grade products in a competitive market. An Alkyd Resin Plant is a specialized manufacturing facility where alkyd resins are synthesized through the process of polyesterification. Alkyd resins are created by reacting polyols (like glycerol), dicarboxylic acids (such as phthalic anhydride), and fatty acids or triglycerides. These plants are equipped with advanced reactors, heating systems, cooling units, and filtration mechanisms to ensure precise production and excellent product consistency.

Applications of Alkyd Resins

Innovative and Efficient Alkyd Resin Plants

With advanced control systems and customizable configurations, these plants cater to a wide range of production needs while ensuring accurate, automated process management. The integration of modern PLC systems enhances monitoring, allowing operators to maintain optimal production conditions with ease. In addition to performance, our plants emphasize energy efficiency and safety. Eco-friendly technologies significantly reduce energy consumption and operational costs, contributing to a more sustainable manufacturing process. Built-in safety mechanisms ensure reliable, hazard-free operations, making our Alkyd Resin Plants a dependable choice for industries seeking quality, flexibility, and environmental responsibility.

Our Alkyd Resin Plants are designed for efficiency and quality, utilizing advanced technology to streamline the manufacturing process. Automatic systems handle raw materials like polyols, acids, and fatty acids, ensuring precision in feeding and storage. The polyesterification reaction is carried out in state-of-the-art reactors with precise temperature control to achieve consistent and high-quality alkyd resin production. Filtration systems effectively remove impurities, delivering a pure and reliable product. Finally, the resin is packaged and stored in durable containers, ready for distribution to meet diverse industrial requirements.

SPECIFICATIONS

Storage Capacity: 50 L TO 20,000 LITER

Machinery in Plant: Chemical Reactor, Column, Condenser, Receiver & blender

Reactor Type: Bottom Dish End, Top Flat End with Motor and Gear box, Inside Agitator for Mixing Material, Bottom discharge connection Vertical Leg Mounted

Usage/Application: Reaction, Mixing or Blending Row Material

Mixing Material: Chemicals / Oils / Lubricant / Liquid Syrup / Sugar Syrup / Wax Melting /Engine Oil

Material: Stainless Steel, Mild Storage

Orientation: Vertical Orientation

Shape: Round

Tank Diameter: As Per Your Requirement

Electric Heater: Single Phase or Three Phase

Temperature Controller: Automatic or PLC Operated

Mixing Speed (RPM): Variable, Speed Up Down as Per Requirement

Finishing Type: Matt Type, Mirror Finishing

Heating and Cooling System: Yes

Temperatures Range: 30 TO 250 Degree

Vacuum: Yes

Cooling Coil: Internal Coil

Outer: Heating coil or jacket

Plat Foam: Mild Steel

INDUSTRIES WE SERVE

- Pharmaceutical industry

- Chemical industry

- Food and beverages industry

- Petro-chemical industry

- Resins industry

- Polymers industry

- Coatings industry

- Adhesives industry

- Agricultural industry

- General chemicals industry

- Plastics industry

- Rubber industry

- Herbal Extractor

Enquiry Now

Ready to Work Together? Build a project with us!