10 Types of Resin Plants and Where They’re Used in Industry

Resin powers everything from the glossy finish on your car to the tough adhesives holding industrial machines together. Behind these everyday essentials is a complex system of resin plants, each designed for a specific job. Some handle high-viscosity polymers, others fine-tune specialty resins for coatings, laminates, or electronics. If you’re part of a manufacturing or chemical processing business, knowing the types of resin plants available, and what they’re built for, isn’t just useful. It’s strategic.

This guide breaks down 10 essential types of resin manufacturing plants, how they work, and where they’re used in industry. Whether you’re scaling up with a pilot resin plant, upgrading to a fully automated setup, or exploring custom resin plant designs, this is the clarity you’ve been looking for.

Built with industry insight from Charmi Engineering, let’s explore what kind of plant fits your process best.

What Is a Resin Plant?

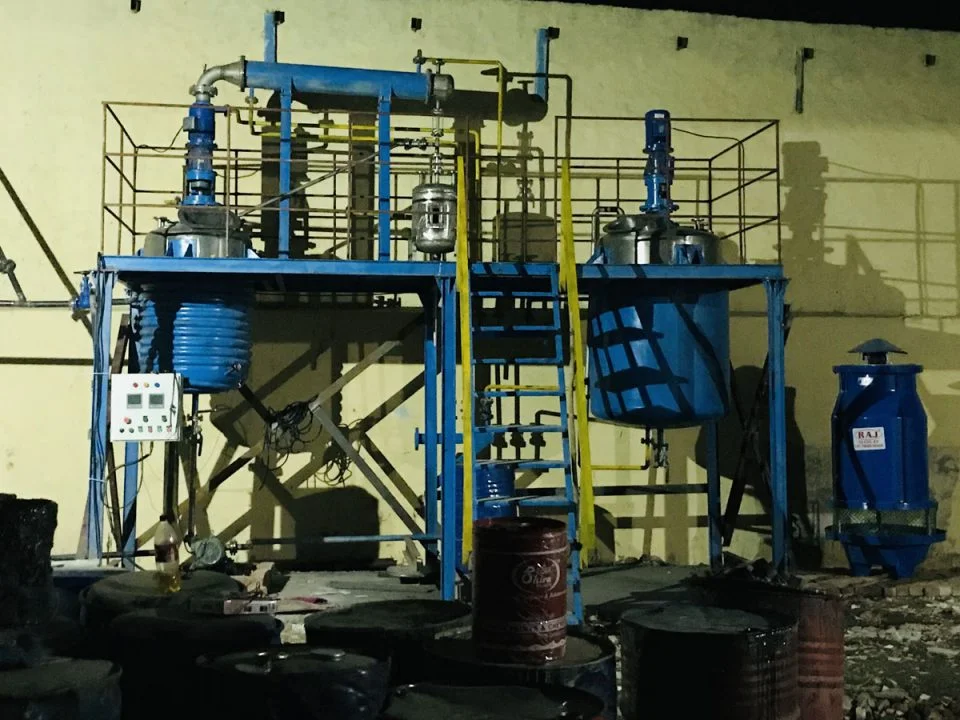

A resin plant is a specialized industrial setup where different types of synthetic or natural resins are produced through chemical reactions such as polymerization or condensation. These plants are designed with various processing units and resin processing equipment like reactors, condensers, mixers, and cooling systems, depending on the type of resin being manufactured.

Why Are Resin Plants So Important in Industry?

Here’s the thing: nearly every major industry, from automotive and construction to electronics and packaging, relies on some form of resin. The industrial resin plant serves as the engine room for producing high-performance materials like epoxy, polyester, or phenolic resins. This makes them essential to:

- Surface coatings and paints

- Adhesives and sealants

- Laminates and molded components

- Electrical insulation materials

- Composite materials for construction and aerospace

1. GP Resin Plant

GP (General Purpose) resin plants are designed to manufacture resins used in basic applications like adhesives, sealants, and laminates. They are cost-effective, easy to set up, and highly scalable. These plants are ideal for:

- Wood coatings

- Paint binders

- Construction adhesives

Resin plant applications for GP resins are broad, making them a great starting point for businesses entering the resin market.

2. Alkyd Resin Plant

Alkyd resins are a key component in paints, varnishes, and industrial coatings. Alkyd resin plants are engineered to produce these oil-modified polyesters efficiently.

Used widely in:

- Decorative paints

- Industrial metal coatings

- Enamel paints

Alkyd resins offer durability and gloss, making them essential for the industrial resin plant segment.

3. Pilot Resin Plant

A pilot resin plant is a small-scale system used for testing and R&D before scaling to full production. Companies use these to:

- Develop new resin formulations

- Test raw material inputs

- Optimize production parameters

These are perfect for startups or R&D departments within larger chemical firms.

4. Unsaturated Polyester Resin Plant

These plants are designed to produce unsaturated polyester resins (UPRs), which are thermosetting resins used extensively in:

- Fiberglass-reinforced plastics (FRP)

- Automotive parts

- Marine vessels

UPR is a must-have in any resin manufacturing plant that targets high-performance composites.

5. Epoxy Resin Plant

Epoxy resin plants manufacture resins known for their excellent adhesion, chemical resistance, and mechanical strength.

Used in:

- Electrical laminates (e.g., PCBs)

- Structural adhesives

- Protective coatings

This plant type requires precision resin processing equipment due to the sensitive nature of epoxy formulations.

6. PVA Emulsion Resin Plant

Polyvinyl acetate (PVA) emulsions are used in:

- Adhesives for wood and paper

- Textile finishes

- Paints and coatings

A PVA emulsion resin plant focuses on water-based systems, making it more environmentally friendly and suitable for sustainable applications.

7. Cardanol Resin Plant

Cardanol Resin Plant, a byproduct of cashew nutshell liquid, is used to produce eco-friendly resins.

Cardanol resin plants are applied in:

- Brake linings

- Varnishes

- Insulation coatings

These plants highlight a shift towards green chemistry in the resin space.

8. Phenolic Resin Plant

Phenolic resins are highly heat-resistant and flame-retardant. Their production requires careful handling due to formaldehyde content.

Common uses:

- Molded automotive parts

- Circuit boards

- High-pressure laminates

This type of resin production plant is essential for electrical and mechanical component industries.

9. Polyester Resin Plant

These are distinct from unsaturated polyester resin plants and are used in:

- Film coatings

- PET production

- Molding compounds

The plant design typically includes esterification reactors and precise temperature controls for optimal polymerization.

10. Phenol-Formaldehyde Resin Plant

These resins are a subset of phenolic resins but offer higher bonding strength and moisture resistance.

Applications:

- Plywood adhesives

- Insulating foams

- Foundry binders

Phenol-formaldehyde resin plants are robust and often part of custom resin plant design projects.

Where Are Resin Plants Used in Industry?

Resin plants play a role in almost every major industry:

- Automotive: Structural parts, coatings, adhesives

- Electronics: Insulators, PCBs, moldings

- Construction: Flooring, sealants, waterproofing

- Marine: Hulls, decks, corrosion-resistant layers

- Furniture: Laminates, wood coatings

Whether you’re building a small resin plant setup or scaling up to a full-fledged industrial resin plant, choosing the right plant type is critical.

Key Considerations for Resin Plant Setup

When investing in a resin plant, consider:

- Scale: Pilot vs commercial

- Raw materials availability

- End-user application

- Environmental regulations

- Automation level

Advanced resin processing equipment and quality control systems ensure consistent product output.

FAQs

What are the different types of resin manufacturing plants?

They include GP, alkyd, epoxy, polyester, phenolic, PVA emulsion, and cardanol resin plants, among others.

What is the best resin plant design for coatings and adhesives?

Alkyd and epoxy resin plants are top choices due to their durability and adhesion properties.

Can I start with a small-scale resin plant setup?

Yes. A pilot resin plant is ideal for small-batch production and R&D.

How are custom resin plants designed?

They are based on end-use application, desired resin properties, batch size, and available utilities.

Are resin manufacturing plants environmentally safe?

Plants like PVA and cardanol resin systems are more eco-friendly. Compliance with pollution control norms is essential for all plants.

Conclusion

Each type of resin plant serves a specific role in India’s growing industrial landscape. From entry-level GP systems to high-performance epoxy and phenolic units, there is a solution for every scale and need. At Charmi Engineering, we deliver fully customizable solutions to help you scale efficiently and responsibly.

If you’re planning your next resin manufacturing plant, make sure it aligns with your product goals, capacity, and compliance needs. The right plant can transform your business. Trust Charmi Engineering for Resin Plant Manufacturing in India.